- AH: What is the back story of the Eck® brand, and what makes it unique?

- RN: Eck® was engineered to prevent the corrosion that occurs when dissimilar metals, such as aluminum and steel, are fastened together. The product was developed as a result of research that was initially focused on finding a solution for the corrosion occurring on fire apparatus.

- Through much research, it was discovered that electrolysis, galvanic, and dissimilar metal corrosion were destroying not only fire apparatus but also trucks, trailers, road signs, buses, aircraft, boats, military equipment, and anything where aluminum was assembled with stainless steel hardware.

- Additionally, road de-icing chemicals such as magnesium chloride and calcium chloride were causing extensive amounts of corrosion, creating safety issues, and shortening the useful life of vehicles. After consulting with chemists and much testing, Eck Complete Corrosion Protection was developed and was ultimately awarded a US patent in 1998.

- AH: What causes corrosion?

RN: There are both chemical and physical causes of corrosion. Corrosion commonly occurs when metal reacts with another substance, such as a different type of metal, dirt, bacteria, etc. Additional factors that can create corrosion (such as rust) include electrochemical processes, temperature changes, physical stress, and the oxidation of air and moisture.

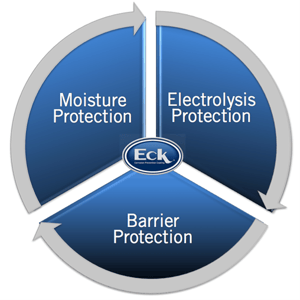

AH: How Does Eck® work to prevent corrosion?

RN: God made dissimilar metals, such as aluminum and steel, not to like each other. Eck® was engineered to prevent this by creating a barrier between the two metals. It uses zinc dust and zinc powder as a sacrificial metal, absorbing the galvanic energy created from dissimilar metal contact.

AH: Is Eck® safe to use on painted surfaces?- RN: Absolutely! When corrosion occurs, it can cause paint to bubble or blister. Eck was designed to prevent this. In fact, three of the world’s largest commercial paint manufacturers tested and endorsed Eck®. They routinely recommend Eck® to their customers, which include truck, automobile, bus, and boat manufacturers.

- RN: Eck was designed primarily to prevent the corrosion of metals, so naturally, it’s safe to use on all metal surfaces.

- AH: Can Eck® be used with electrical connectors?

RN: Yes. Several customers use Eck® every day to prevent corrosion on electrical connections. It works as a dielectric grease with corrosion-preventing ingredients.

AH: What industries can benefit from Eck® products?

RN: Many industries, some that might even surprise you, use our patented Eck® corrosion prevention coating.

- Aerospace Industry- Boat & Ship Builders

- Bus & Transit Manufacturing

- BBQ Grill, Outdoor Kitchen & Patio Furniture

- Lift Gate Manufacturers

- Lights & Electrical Connections (Eck® is dielectric)

- Recreational Equipment

- Road Sign & Traffic Lights

- Road & Bridge Construction

- Semi-Trailer

- Stairs & Railing Manufacturing

- Swimming Pool

- Swing Set

- Tooling & Die

- Tractor & Lawn Equipment

- Trains & Railcar Manufacturing

- Utility Trucks & Trailers

- Weather monitoring equipment

- AH: Has Eck® been lab-tested, and is it safe?

RN: Eck® has been rigorously tested in the field as well as in the lab. Lab results show Eck® successfully passing a 4,000-hour test. We can provide pictures and other testing information for anyone who wants to learn more. Additionally, Eck® has been tested by an independent laboratory and found to be well above the OSHA and ACGIH standards, making it safe to use.

- AH: Do any customer reviews, testimonials, or highlights stand out?

- RN: Eck® has many success stories, but one that stands out is from a Fire Truck manufacturer dealing with corrosion warranty claims that cost them over $4 million annually. Using Eck® Corrosion Coating brought those warranty claims down to next to nothing. Proper Eck® applications will keep customers happy and eliminate corrosion warranty costs.

- Here are a couple of other customer testimonials:

“The corrosion issue caused by these anti-ice chemicals is an industry-wide problem. We chose the Eck® coating to provide our customers with a value-added solution for corrosion prevention."

- Director of Engineering, East Manufacturing

"We love Eck®. It's better and faster than using Mylar tape. Eck® saves us time and money."

- Product Manager, MAC Trailer Manufacturing

AH: How do customers know which Eck® packaging option is right for their applications, and how can they purchase it?

RH: Eck is available in various packaging options for any application. Choose from 12 oz spray cans, quart cans, 3.75 oz tubes, and mini 0.5 oz tubes.

To learn more about this patented, innovative solution and to place an order, please visit our official page here: info.austinhardware.com/eck