Adhesives vs. Mechanical Fasteners: Choosing the Right Solution for the Job

Topics: Blind Rivets, adhesives,sealants,chemicals

The Importance of Testing and Quality Control for Rivets.

The Importance of Testing and Quality Control for Rivets

The importance of working with rivet manufacturers whose testing and quality assurance programs meet regulatory requirements to produce certified rivets cannot be overstated. A structure or equipment's performance will be only as reliable and safe as the rivets that hold it together. Rivet manufacturers must adhere to rigorous testing protocols and quality standards to guarantee that their rivets will perform as expected.

Topics: Austin Engineered Solutions™, fasteners, Blind Rivets

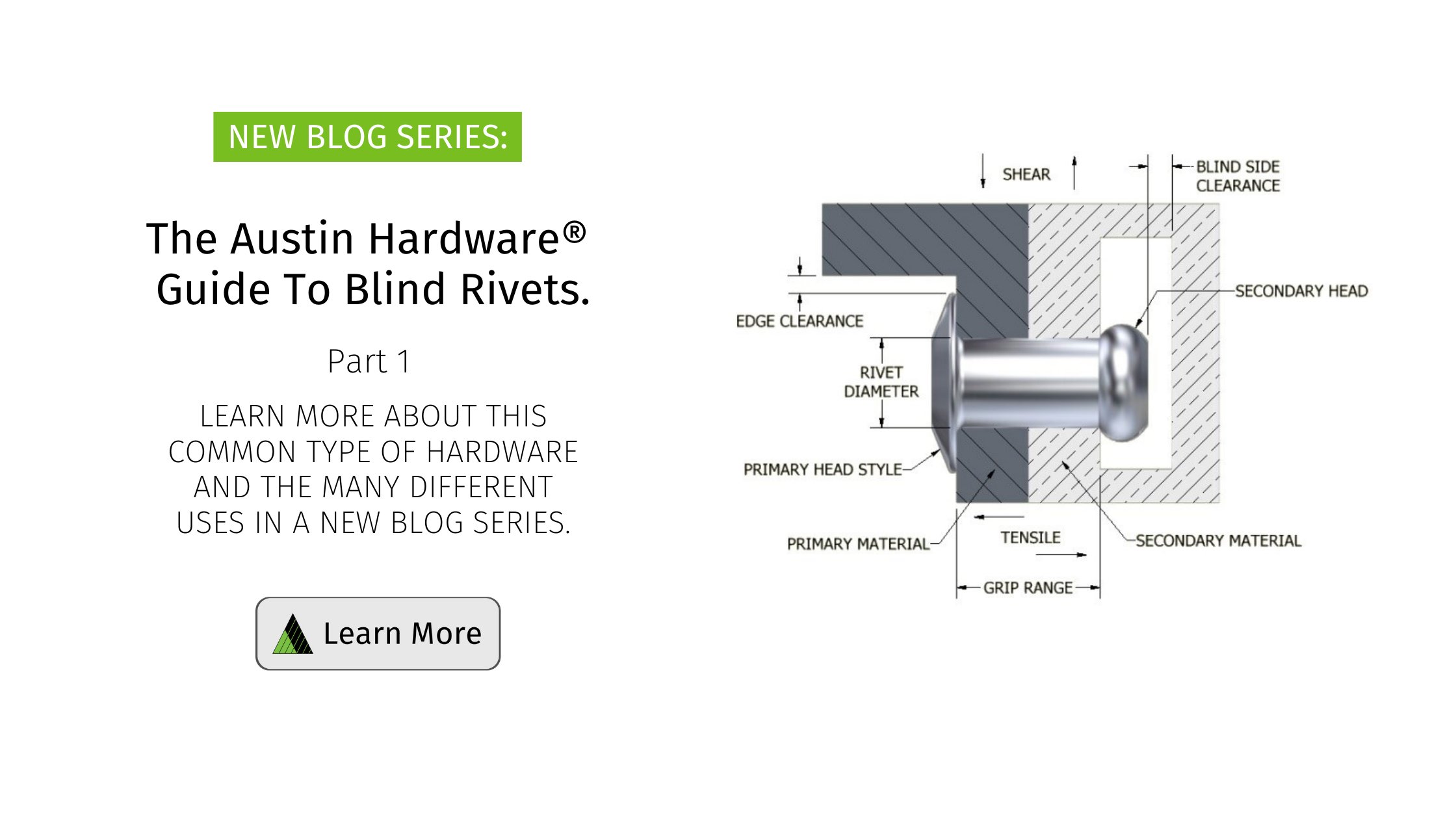

Blind rivets have several advantages over other permanently installed fasteners, such as solid or semi-tubular rivets, clinch fasteners, and traditional nuts and bolts. Because they can be installed from one side of the application, their use is paramount when the back side of an application is limited or non-existent. This also makes them more cost-efficient and versatile than other types of fasteners.

The Basic Elements of Blind Rivets

There are four basic elements to a blind rivet:

- 1. Material

- 2. Diameter

- 3. Grip Range

- 4. Head Style

Blind rivets are available in a wide range of materials, diameters, grip ranges, and head styles, allowing them to be used in a wide array of applications. We will explore these elements further and discuss their significance in maximizing joint integrity.

MATERIAL

While most common blind rivets are available in aluminum, steel, and stainless steel, they are also available in copper, brass, and plastic. These softer rivets have become more common with the increased use of composite materials.

A good rule of thumb when selecting a blind rivet is to use the same material rivet as the substrate into which it is being installed. If you are riveting sheets of steel together, use a steel rivet. The same goes for aluminum and stainless steel. This is important because, depending on the environment, using dissimilar metals may result in galvanic corrosion. In cases where this rule cannot be followed, consider using Eck Complete Corrosion Control, which you can learn more about HERE.

Topics: Vendor Managed Inventory, Austin Hardware® News, fasteners, Blind Rivets

The Austin Hardware® Guide to Blind Rivets, Part One

This is Part 1 of a 4-part series on Blind Rivets.

What is a blind rivet? Simply put, it's a rivet that can be installed from just one side of the application, thus the term "blind."

The development of blind rivets can be traced back to the aircraft industry.

According to Assembly magazine,

"The blind rivet was originally developed as a replacement fastener for solid rivets where service repair was required. Blind rivets also trace their roots to the aircraft industry. Before blind rivets were widely accepted, installation of solid aluminum rivets in fuselages, wings and other airframe components typically required two assemblers: one person with a rivet hammer on one side of the structure and a second person with a bucking bar on the other side. Since rivets were often inaccessible from both sides of the work, this assembly process was extremely slow and very time consuming."

Continuing with the history lesson, blind rivets were initially dubbed "pop rivets" because of the popping sound made during installation when the stem (a.k.a. mandrel) breaks off. Later, the originating company branded its version of blind rivets as POP® rivets. To this day, blind rivets are generically known as "POP rivets," much the same way tissues are referred to by the prominent brand Kleenex. But in reality, while all POP® rivets are blind rivets, not all blind rivets are necessarily the POP® brand. Interestingly, while the roots of the original POP® fasteners live on, the company is now a part of STANLEY Engineered Fasteners, a division of Staley Black & Decker.

Topics: Austin Hardware® News, Blind Rivets, Blog