In the past, warehouse operations were highly dependent on dozens of trained employees operating expensive loading and shipping equipment. Compared to the modern era, the 20th-century warehouse industry work was error-prone, relatively expensive, and labor intensive.

What's more, anticipated technological developments in the industry are prone to drastically increase warehouse operation productivity and reduce costs in myriad ways.

Contemporary Changes in the Warehouse Work Setting

In order to understand the future of the warehouse space, you must first comprehend modern developments in the industry. Due to the incorporation of computer technology, the use of paperwork has sharply declined thus reducing issues caused by readability problems and missing paper.

Further, the implementation of a mixture of human and computer-assisted warehouse management system in combination with the drive to improve shipping efficiency, logistics management has changed also.

In the past, direct-to-store delivery, in which a retailer receives its goods immediately from the supplier was standard practice. However, industry titans, such as Walmart, are switching to a centralized shipping distribution model. With this model, suppliers deliver products to centralized warehouse locations. The products are then loaded onto transportation trucks and shipped to retailers as needed.

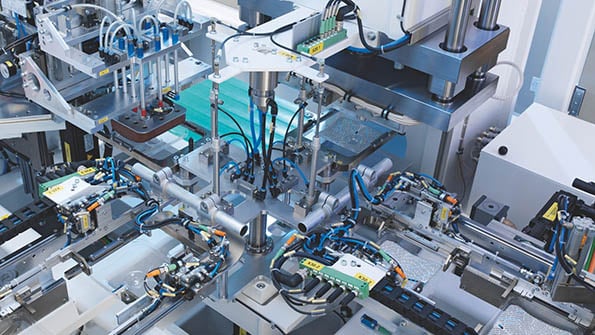

Automation of the Warehouses Industry

In the coming decades, the continuation of the existing automation trend is likely to accelerate. Specifically, with the creation of increasingly sophisticated AI, work management systems are predicted to perform an entire facility's inventory management bereft of any human intervention.

On top of that, human workers will become displaced due to the production of fully automated robotic equipment which can move, store, and retrieve items.

A glimpse into that future has already been seen in Falkenberg, Sweden wherein a large brewing company, Carlsberg Group, is phasing in the use of laser-guided forklifts which transport pallets without any human operators. In addition to improving safety and reducing product damage without any significant downtime during the transition, Carlsberg has reported a marked increase in warehouse productivity.

Additional Effects of Nascent Computer Technology

The effects of a robotic warehouse will also improve the conditions in which items are stored. With little to no human presence in an automated warehouse, the need for lighting will be significantly reduced, if not eliminated.

Further, without having to take into account the comfort of human workers, temperatures can be set at whatever levels would be optimal to store the goods placed in the warehouse. As a consequence, mass storage companies will save significantly on facility heating and electrical costs.

Lastly, the means by which firms in the warehouse business attract clients and compete with each other is changing as well. Like innovation-focused companies in other industries, Austin Hardware & Supply Inc. will incorporate what is known as “immersive marketing experiences.” As stated in an anticipated press release, we will be using augmented reality advertisements, along with other novel technologies, to gain new customers.

To summarize, the warehouse industry will become even more automatized, dependent almost entirely on mechanical rather than human labor, and considerably cheaper to manage.