.png?width=1200&name=Clinch%20Fastener%20Blogs%20(1).png)

Clinch Fasteners

Clinch or self-clinching fasteners are typically used for metal assemblies that may be too thin for tapping or in applications where it’s not feasible to employ stamped or extruded threads.

Self-clinching fasteners are found in household appliances, electronics, medical equipment, telecom equipment, automotive and transportation markets, and many other industrial applications.

According to a Machine Design article, The Basics of Self-Clinching Fasteners, the first self-clinching fasteners were invented in the 1940s to allow manufacturers to attach components to thin ductile metal and ensure the connection could withstand hard tugs and torque loads.

When used in sheet metal, clinch fasteners allow for secure fastening that would otherwise not be possible. As described in the Design World article, How to test self-clinching fasteners for reliability, “Self-clinching fastener nuts have thread strengths that are greater than milled steel screws, and are commonly used wherever strong internal threads are needed for component attachment or fabrication assembly.”

Design World continues, “Upon installation, self-clinching fasteners provide permanent and reusable load-bearing threads to accept mating hardware in metal sheets too thin to be tapped or where extruded or stamped threads would be impractical. They become integral parts of an assembly, will not loosen or fall out (even when the mating thread is removed), never have to be restrained from rotation with a tool, and never have to be handled again.”

Design World continues, “Upon installation, self-clinching fasteners provide permanent and reusable load-bearing threads to accept mating hardware in metal sheets too thin to be tapped or where extruded or stamped threads would be impractical. They become integral parts of an assembly, will not loosen or fall out (even when the mating thread is removed), never have to be restrained from rotation with a tool, and never have to be handled again.”

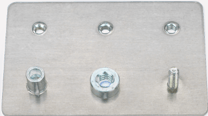

While there are innumerable variations of self-clinching fasteners, three of the primary types include Standoffs, Nuts, and Studs. Each of those may have a head that is flush or concealed.

Standoffs are very commonly used in PCB’s (printed circuit boards) and other electrical assemblies to protect fragile circuitry and electrical connections. Self clinching standoffs eliminate the need for loose hardware on aftermarket components.

Standoffs are very commonly used in PCB’s (printed circuit boards) and other electrical assemblies to protect fragile circuitry and electrical connections. Self clinching standoffs eliminate the need for loose hardware on aftermarket components.

Nuts provide a strong base for accepting bolts and screws in a large variety of thin sheet metal applications.

Studs provide permanent threads with high torque and pushout resistances in any thin sheet metal or non-metal application.

in any thin sheet metal or non-metal application.

Steave Klein, National Sales Manager for Fasteners with Austin Hardware®, notes, “The design parameters of your application will dictate the type and style of clinch fastener needed. For example, a flush fastener can be specified if your application requires flushness for clearance purposes. Stainless steel clinch fasteners are available for applications in which the material must be non-corrosive. The application options are boundless, but one of the great benefits of using clinch fasteners is that despite innumerable potential configurations, all are installed basically the same way.”

Austin Hardware® offers a full line of clinch fasteners. We can help guide you to the proper clinch fastener for your application with basic technical support, or when appropriate, we can bring in our vendor partners to help find just that right clinch fastener for your needs.