Rob Dell'Elmo

Recent Posts

Final Results of Austin Hardware's 9th Annual Charity Football Pool

Make-A-Wish America Wins Big Thanks to Austin Hardware's 8th Annual Charity Football Pool

Winner David Famula selects Make-A-Wish America to receive a donation!

With football season coming to its conclusion on Sunday, we want to share the results of our 8th Annual Austin Hardware® Charity Football Pool.

This year’s contest went 12 weeks into the 2023-24 season. The player who outlasted the competition this year is David Famula from Germany.

David beat out our runner-up, Robert Carmer, on the Monday night of week #12 when the Chicago Bears upset Robert's pick, the Minnesota Vikings, on Minnesota's home field. This result gave David the victory, as he had already gotten a Week #12 victory when the Los Angeles Rams defeated the Arizona Cardinals that Sunday afternoon.

Technological and Social Hurdles for Multi-Channel Distributors with Multiple Locations

Modern multi-channel distribution across multiple locations presents various technological and social hurdles.

Infrastructure, integration, data synchronization, security, and privacy issues are vital from a technological standpoint.

Ensuring a Robust Infrastructure

Ensuring a robust and reliable technology infrastructure is in place to support multi-channel distribution can be a significant challenge. Reliable network connectivity, efficient data storage and retrieval systems, and scalable hardware and software solutions are important.

Looking for a unique solution that stops the corrosion of metals in its tracks? Discover our patented formula, ECK by Austin Hardware®.

When two different types of metals are joined together, a process called ELECTROLYSIS can occur. Also known as galvanic corrosion, electrolysis happens when two dissimilar metals are directly connected, causing the lesser of the two metals to corrode. For the process to occur, the two metals must also come into contact with a conductive electrolyte. Ultimately, this can result in damage to the joint, causing the metals to fail.

Several factors contribute to electrolysis when joining dissimilar metals, including differences in electrical potential, composition, and exposure to moisture or other corrosive substances. Let's take a closer look at each of these factors and how they can impact the durability of the joint.

Topics: Austin Engineered Solutions™, eck

An Explanation of Common Gas Springs: How Do They Work?

An Explanation of Common Gas Springs: How Do They Work?

Gas springs, also known as gas struts or gas lift supports, use compressed gas to provide smooth and controlled motion of lids, hatches, flaps, and more in many applications. Common examples include automotive hoods, furniture, medical equipment, and industrial machinery.

They work on the principle of the ideal gas law, which states that the pressure of a gas is directly proportional to its temperature and the number of molecules present in the container.

A typical gas spring consists of a piston rod and a cylinder filled with pressurized gas, usually nitrogen. When the gas spring is extended, the gas pressure inside the cylinder pushes the piston rod out. Conversely, when the gas spring is compressed, the gas pressure inside the cylinder decreases, allowing the piston rod to retract.

Topics: Austin Engineered Solutions™, Products (General), Genesis™

Learn More About the Differences Between VMI and CMI.

The Differences Between VMI and CMI

Vendor Managed Inventory (VMI) and Customer Managed Inventory (CMI) are inventory management programs that differ in responsibility for managing inventory.

In a VMI program, the vendor (supplier) manages the customer's inventory levels. The vendor collects customer usage data from sales forecasts, inventory levels, or other key metrics to determine when and how much product to deliver. In a VMI program, the vendor takes on the responsibility, and subsequent risk, of maintaining appropriate stock levels to balance inventory with costs for optimal cash flow. The customer benefits from a more streamlined supply chain and reduced inventory holding costs while having to invest less time and personnel resources into inventory management.

Learn more About Using Austin Hardware's Complete Line of Super Heavy Duty Drawer Slides.

Austin Hardware®, Football Pool Sponsors Come Up Big for Charity This Season.

New Product Release! Third Generation LifeDefender™ Updates are Designed With End-User's Needs In Mind.

EMTs, paramedic’s and other critical care workers have an incredible responsibility and they’re often doing it while racing to the hospital and against the clock. They don’t have time to think about their own safety while caring for a patient. LifeDefender™ Cabinet Security Frames were developed with these dedicated workers and their patients in mind. The 3rd generation of this revolutionary product is the fruit of the feedback from ambulance manufacturers and their customers.

Improved features in the 3rd generation updates include:

- An optional key locking feature is now available pre-installed for both the fixed and restocker (a.k.a. "speed-load") frames.

- Tag brackets, an optional inventory control feature that can be pre-installed onto the frame, have been improved with more mounting options and soft, over-molded covers on exposed areas.

- The slider handles have been redesigned smaller while maintaining the same operation and latching function. The smaller size allows the slider to open further, providing an extra inch of access space when the slider is open.

- Hinges are now anodized aluminum to improve the appearance against the frame as well as cosmetic durability.

- To more easily adjust a cabinet's latch clearance and door position, the hinge shims have been improved with all hole locations now slotted, allowing the shims to be added or removed between the hinge and cabinet without removing the hinge screws.

- Frames are now available with an optional pre-installed protective film on the outer frame. The film can remain on the frame without affecting the frame function.

- Fixed-frame LifeDefender™ units now include a new tether system to provide an extra connection between the cabinet and frame, which is especially helpful in wooden cabinets.

- Unframed LifeDefender™ doors (CW series) are now available with pre-engineered motion control options (gas springs or dampers) to move and hold the door in its open position.

Topics: ambulances, Essential EMT, LifeDefender™

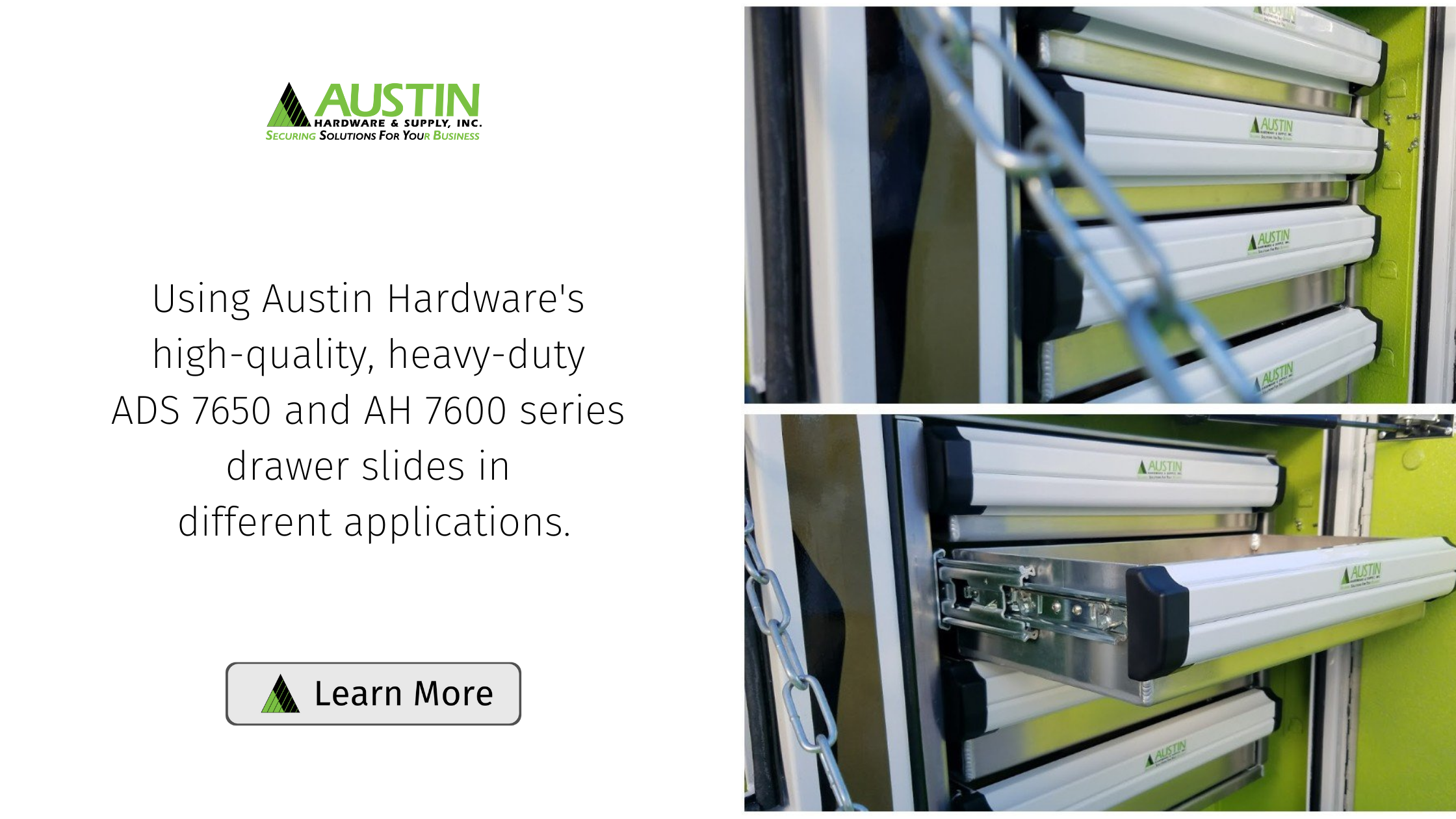

Using Austin Hardware's High-Quality, Heavy-Duty ADS 7650 and AH 7600 Series Drawer Slides in Different Applications.

The ADS 7650 and AH 7600 series side mount drawer slides from Austin Hardware® are high-quality, heavy-duty slides representing two of the best drawer slide options available.

Both are found extensively in emergency vehicles, utility bodies, cargo vans, maintenance trucks, recreational vehicles, and many other vehicular and non-vehicular applications. This is because their durability, flexibility, and ease of use are second to none.

Both series’ have a load rating of up to 500 lbs. per pair, making them suitable to store all types of valuable cargo. The slides are tested at the 18” length but have been shown to perform to this rating up to 28”.

The AH 7600 is the original, non-locking version of this slide. It is sold in pairs for applications where a lock is not required or desired.

Topics: Blog, drawer slides