.png?width=2240&name=Austin%20Ads%20(4).png)

This is Part 1 of a 4-part series on Blind Rivets.

What is a blind rivet? Simply put, it's a rivet that can be installed from just one side of the application, thus the term "blind."

The development of blind rivets can be traced back to the aircraft industry.

According to Assembly magazine,

"The blind rivet was originally developed as a replacement fastener for solid rivets where service repair was required. Blind rivets also trace their roots to the aircraft industry. Before blind rivets were widely accepted, installation of solid aluminum rivets in fuselages, wings and other airframe components typically required two assemblers: one person with a rivet hammer on one side of the structure and a second person with a bucking bar on the other side. Since rivets were often inaccessible from both sides of the work, this assembly process was extremely slow and very time consuming."

Continuing with the history lesson, blind rivets were initially dubbed "pop rivets" because of the popping sound made during installation when the stem (a.k.a. mandrel) breaks off. Later, the originating company branded its version of blind rivets as POP® rivets. To this day, blind rivets are generically known as "POP rivets," much the same way tissues are referred to by the prominent brand Kleenex. But in reality, while all POP® rivets are blind rivets, not all blind rivets are necessarily the POP® brand. Interestingly, while the roots of the original POP® fasteners live on, the company is now a part of STANLEY Engineered Fasteners, a division of Staley Black & Decker.

While blind rivets are often associated with aircraft, they're also used widely in many other industries. They're commonly used in the transportation industry on trucks, automobiles, busses, railcars, RVs, and more. Blind rivets are also used to assemble equipment in the telecom and HVAC industries and fabricators in a multitude of other manufacturing sectors. Because blind rivets can be installed from one side of the application, they offer a major advantage over other permanently installed fasteners, such as solid or semi-tubular rivets, clinch fasteners, and traditional nuts and bolts. This is critical when access to the backside of an application is limited or non-existent. Because blind rivets are installed from only one side, this often makes them more cost-efficient and versatile than other types of fasteners.

Because blind rivets can be installed from one side of the application, they offer a major advantage over other permanently installed fasteners, such as solid or semi-tubular rivets, clinch fasteners, and traditional nuts and bolts. This is critical when access to the backside of an application is limited or non-existent. Because blind rivets are installed from only one side, this often makes them more cost-efficient and versatile than other types of fasteners.

When using blind rivets, there are several key elements to consider in order to maximize joint integrity. We'll discuss two of those in this post, then dive into the others in part 2.

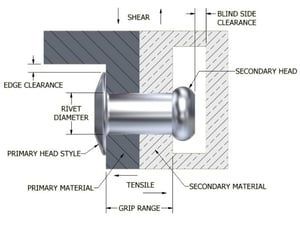

The two most important factors are Grip Range and Hole Size.

- Grip Range - This is the total material thickness in which the rivet is designed to work. When specifying a blind rivet,

simply follow the manufacturer's guidelines for the total material thickness that the rivet is designed to fasten. There will be a minimum and maximum thickness, typically in increments of approximately .060". Sounds simple, right? It is, however, it's also one of the most common mistakes made. Using a blind rivet out of its stated grip range can cause joint degradation resulting in looseness or malformation of the rivet.

simply follow the manufacturer's guidelines for the total material thickness that the rivet is designed to fasten. There will be a minimum and maximum thickness, typically in increments of approximately .060". Sounds simple, right? It is, however, it's also one of the most common mistakes made. Using a blind rivet out of its stated grip range can cause joint degradation resulting in looseness or malformation of the rivet. - Hole Size - All blind rivets have a recommended hole size into which they can be installed. This is critical because blind rivets are designed to expand and pull-up within their recommended hole. If the hole is too large, the rivet can't expand enough to properly "fill the hole," resulting in less pull-up and loose joints. If the hole is too small, you'll either have trouble fitting the rivet through, or result in a "shear point" forming in the rivet body, which could lead to the rivet shearing off and failing in the application.

In our second post, we'll discuss the final two most important factors that must be considered to maximize joint integrity when using blind rivets.

If you have any questions about using blind rivets in your application, contact your nearest Austin Hardware® location to discuss the options.