.png?width=880&height=469&name=_Blog%20Banner%20(1).png)

What is a Gas Spring?

Have you ever wondered how a gas spring works? Or maybe you don’t even know what one is. You would be surprised, though, by how much you use them in your daily life. Have you ever tried opening the trunk of your car? Or raised an office chair to desk level?

What you probably used as a gas spring. There are so many common daily uses for these helpful springs. They are most commonly used for doors but have a wide variety of applications. A gas spring works by using compressed gas to maneuver two different parts a 1) piston rod and a 2) cylinder. The gas compression creates a strong force, which is proportional to an increase in pressure as the two mechanisms work together. Even a small gas spring can generate a lot of force and, therefore, has impressive strength.

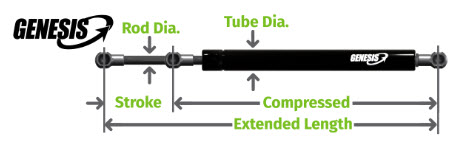

Terminology for parts of the Gas Spring

- Stroke – The maximum length the rod can travel from compressed length to extended length.

- Compressed Length – The length when the gas spring is closed.

- Extended length – The total length of the gas spring when extended fully.

- Rod & Tube – These are the parts that make up the essential mechanical elements of the gas spring.

Common Applications & Industries

- Automotive, recreational, and agricultural vehicles

- Office equipment

- Machinery and industrial equipment design

- Medical and Aircraft Industry

Benefits:

- Easy to install

- Strong / Durable

- Variety of Sizes and Materials Available

- Improves ergonomics in most applications

- Cost-effective and long-lasting

How to Find the Right Gas Spring

Due to the versatility of gas springs, they can be used for a variety of applications, from small in-home use to large industrial equipment. So, how do you find the right gas spring for the job? First, you need to know the basics of the project or application; this will help you determine the size of the gas spring you need to use. You will need to know the weight of the lid or door that you wish to support, the length of your lid or door, and how far you want your door to open (45⁰, 60⁰, 90⁰, etc.).

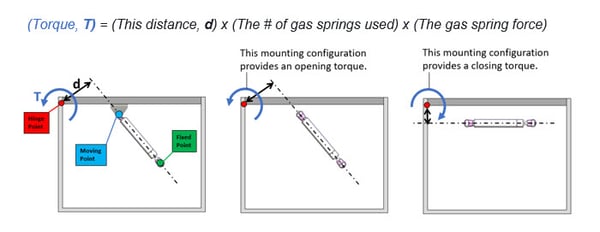

Choosing the appropriate mounting locations will be key to achieving the desired handle efforts for your application.

- The gas spring mounting location that is attached to the lid is referred to as the “Moving Point” because it is the point that moves with the lid as it is opened and closed.

- The gas spring mounting location that is attached to the box is referred to as the “Fixed Point” because it remains fixed or stationary as the lid is opened and closed.

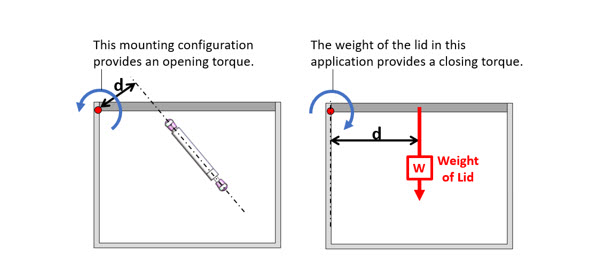

- When mounted, the force of the gas spring provides a torque around the center of the hinge pin of the box or door. The magnitude and direction of the perpendicular distance (from the line of action of the gas springs to the center of the hinge pin) greatly impacts the opening torque provided by the gas springs (illustrated below).

Ideally, mounting locations will be chosen that provide torque values that mostly counter the torque created by the weight of the lid, throughout its opening motion.

You will also need to choose mounting points that will allow the lid to fully close.

- The available stroke for any gas spring is always less than half of the extended length of the gas spring.

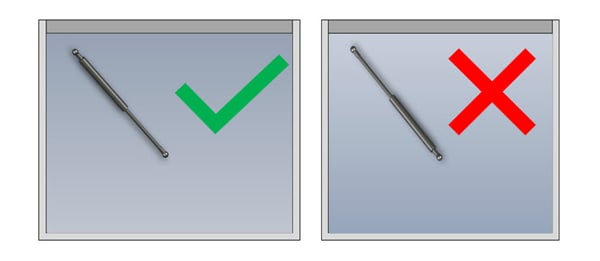

- When considering which end of the gas spring to mount to the lid and which to mount to the box, it is important to mount the gas spring so that the gas spring shaft is pointing towards the ground. This will provide a smooth, oil dampened, motion and maximize the gas spring’s cycle life by continually lubricating the shaft.

Finally, you can determine which type of material would be best, as there are a few different materials used to make gas springs. Luckily, Austin Hardware’s Genesis Gas Springs Part Finder makes it easy for you to find the parts you need. You can choose from seven different options and make your selection based on these factors. You can also speak to a product expert by visiting our contact us page.

Want to learn more: https://www.austinhardware.com/all-products/gas-springs.html