An Explanation of Common Gas Springs: How Do They Work?

Gas springs, also known as gas struts or gas lift supports, use compressed gas to provide smooth and controlled motion of lids, hatches, flaps, and more in many applications. Common examples include automotive hoods, furniture, medical equipment, and industrial machinery.

They work on the principle of the ideal gas law, which states that the pressure of a gas is directly proportional to its temperature and the number of molecules present in the container.

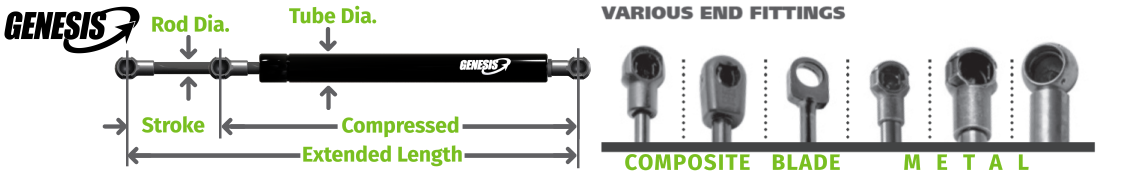

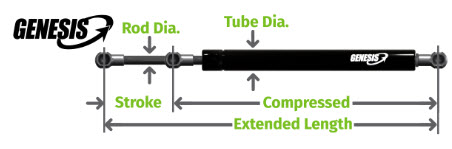

A typical gas spring consists of a piston rod and a cylinder filled with pressurized gas, usually nitrogen. When the gas spring is extended, the gas pressure inside the cylinder pushes the piston rod out. Conversely, when the gas spring is compressed, the gas pressure inside the cylinder decreases, allowing the piston rod to retract.

The movement of the piston rod is controlled by a valve that regulates gas flow between the two sides of the piston. When the valve is opened, the gas can flow freely, allowing the piston rod to move quickly. When the valve is closed, the gas is forced to flow through a small orifice, slowing down the piston rod's movement and providing a damping effect.

Gas springs are designed to provide reliable, maintenance-free operation for an extended period of time when used appropriately and installed correctly. Your gas springs' performance and longevity depend upon a combination of choosing the right size and type of gas spring for a given application, the correct installation, and operating conditions.

Ideal operating conditions are variable and involve temperature, orientation, mounting, lubrication, pressure, and environmental considerations. Following the manufacturer's recommendations and guidelines for proper use and maintenance is always essential.

Here are some general guidelines for ideal operating conditions for gas springs:

- Temperature: The temperature range for gas springs is typically between -22°F to 176°F. However, the specific temperature range may vary depending on the type of gas spring and the application.

- Orientation: Most gas springs are designed to be installed with the rod end down in the vertical position to prevent malfunction and damage and maximize life expectancy.

- Mounting: Secure mounting with appropriate mounting hardware is paramount to withstand the forces applied by the gas spring.

- Lubrication: Proper lubrication is vital to ensure the smooth operation of a gas spring. The type of lubricant used should be compatible with the gas spring and the application.

- Pressure: The pressure inside the gas spring should be within the manufacturer's recommended range. Excessive pressure can cause the gas spring to fail, while too little pressure can result in inadequate support.

- Environment: Gas springs can be affected by exposure to chemicals, moisture, and other environmental factors. Considering these factors when specifying a gas spring for any application is important.

Austin Hardware's line of Genesis™ gas springs offers something for every application and operating condition.

For help selecting the right gas spring for your application, check out our Gas Spring Finder, or call your nearest Austin Hardware® location to speak with an experienced and knowledgeable customer service representative.