Maximizing Efficiency with Vendor Managed Inventory and eTurns TrackStock for High-Turn Items

Topics: Vendor Managed Inventory, inventory management, fasteners

The Benefits of Pre-Packaged Fasteners for DIY and Dealers

Pre-packaged fasteners offer substantial benefits for DIYers, dealers, and retailers alike. For DIY enthusiasts, they bring convenience and organization while also providing versatility and cost savings. For dealers and retailers, pre-packaged fasteners simplify inventory management, reduce customer confusion, and offer a cost-effective solution to meet customer demands. Embracing pre-packaged fasteners is a win-win situation with benefits for everyone involved. Let’s explore some of these benefits further.

In the worlds of DIY projects, vehicular and industrial production, and repair, fasteners are the unsung heroes that literally hold things together. From hex head cap screws and carriage bolts to blind rivets and washers, each fastener type plays a specific and important role in ensuring structures remain intact.

Pre-packaged fasteners are convenient and efficient, eliminating the hassle of sifting through bins or making multiple trips to a hardware store. Whether working on a home project, manufacturing goods such as truck bodies or trailers, or making equipment repairs, having the right type and number of fasteners on hand simplifies the process.

Pre-packaged fasteners reduce customer confusion and product handling time for dealers and retailers. Rather than stocking fasteners in bulk and dealing with inventory complexity, pre-pack fasteners can be quickly restocked and sold, making the process more streamlined for sellers and customers.

Topics: fasteners

The Importance of Testing and Quality Control for Rivets.

The Importance of Testing and Quality Control for Rivets

The importance of working with rivet manufacturers whose testing and quality assurance programs meet regulatory requirements to produce certified rivets cannot be overstated. A structure or equipment's performance will be only as reliable and safe as the rivets that hold it together. Rivet manufacturers must adhere to rigorous testing protocols and quality standards to guarantee that their rivets will perform as expected.

Topics: Austin Engineered Solutions™, fasteners, Blind Rivets

Fabricators that work with removable panels need an efficient and reliable way to install them. However, the processes and hardware used significantly impact the end product. This post explains how to install a removable panel and select the proper hardware.

Removable panels are used widely across many industries, including signage, marine, interior design, and public transportation. While these industries have unique application requirements, they do have one thing in common: By design, removable panels will be attached and reattached dozens or even hundreds of times. So, before you begin the installation, it’s crucial to identify hardware and mounting methods that are strong and durable enough to handle repeated installation.

Step #1: Select Your Hardware

When most people think of removable panels, the first thing that comes to mind is the panels themselves. But the signature feature of removable panels – the ability to remove them – comes from what you don’t see: the hardware.

The success of a removable panel relies heavily on the strength and quality of the fastening system. So, before you begin installation, it’s worth taking the time to understand the hardware that makes it all possible.

Plastic fasteners are most commonly used to mount removable panels. Their low price and availability have made them the go-to for this installation. However, several problems might occur with plastic fasteners. They offer low durability and will fatigue after prolonged use. Their longevity depends on the specific product, but as a rule, plastic fasteners will degrade, warp, or break after repeated removal of the panel. When this happens, the panels will be difficult to remove or reattach, and there’s a good chance all of the hardware will have to be replaced.

Topics: Innovative Solutions, fasteners, rv

Blind rivets have several advantages over other permanently installed fasteners, such as solid or semi-tubular rivets, clinch fasteners, and traditional nuts and bolts. Because they can be installed from one side of the application, their use is paramount when the back side of an application is limited or non-existent. This also makes them more cost-efficient and versatile than other types of fasteners.

The Basic Elements of Blind Rivets

There are four basic elements to a blind rivet:

- 1. Material

- 2. Diameter

- 3. Grip Range

- 4. Head Style

Blind rivets are available in a wide range of materials, diameters, grip ranges, and head styles, allowing them to be used in a wide array of applications. We will explore these elements further and discuss their significance in maximizing joint integrity.

MATERIAL

While most common blind rivets are available in aluminum, steel, and stainless steel, they are also available in copper, brass, and plastic. These softer rivets have become more common with the increased use of composite materials.

A good rule of thumb when selecting a blind rivet is to use the same material rivet as the substrate into which it is being installed. If you are riveting sheets of steel together, use a steel rivet. The same goes for aluminum and stainless steel. This is important because, depending on the environment, using dissimilar metals may result in galvanic corrosion. In cases where this rule cannot be followed, consider using Eck Complete Corrosion Control, which you can learn more about HERE.

Topics: Vendor Managed Inventory, Austin Hardware® News, fasteners, Blind Rivets

Your Complete Guide to Fastener Nuts, A New Austin Hardware® Two-Part Blog Series, Pt.2.

In a previous post, we discussed many of the different types of standard fastening nuts. In this edition, we’ll talk about locknuts. The major difference between standard nuts and locknuts is standard nuts consist simply of a threaded hole, while locknuts are designed to prevent loosening when exposed to vibration. As with standard nuts, there are many different variations of locknuts from which to choose. We’ll take a look at some of the more popular locknuts here.

Topics: Products (General), fasteners, Blog

Your Complete Guide to Fastener Nuts, A New Austin Hardware® Two-Part Blog Series.

Topics: Vendor Managed Inventory, fasteners, Blog

Austin Hardware Fastener Blog Series: Blind Bolts Explained.

The speed and ease of installation of blind fasteners make them an excellent choice for manufacturers of all types of products. This is especially true when access to an application's backside is limited at best or completely inaccessible.

Once determined that a blind fastener is right for the application, the user then must decide which type of blind fastener is most appropriate. While many factors could play into this decision, strength requirements and vibration resistance are two criteria that sit at the forefront.

For lighter duty applications that are not load-bearing (under 100 lbs. of shear and tensile strength), a standard blind rivet is often adequate. For more information on standard blind rivets, check out our four-part series on blind rivets.

Topics: fasteners

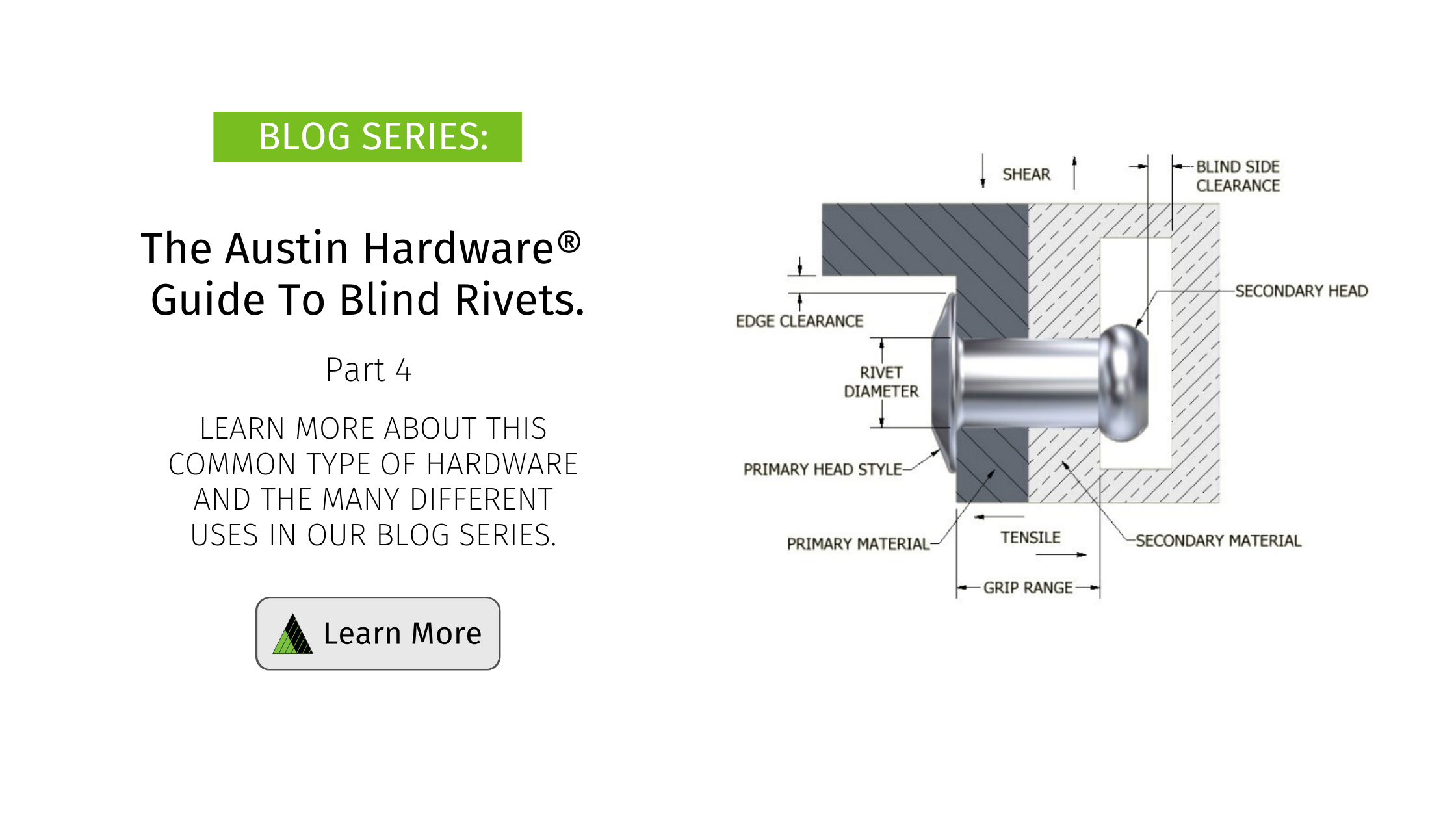

The Austin Hardware® Guide to Blind Rivets, Part Four

This is Part 4 of a 4-part series on Blind Rivets

In the first three parts of our series on blind rivets, we discussed the history of blind rivets; the most important factors to maximize joint integrity (grip range, hole size, material, and installation tooling); rivet selection (material, diameter, grip range, head style), and the most common types of blind rivets (drive-pin and break-stem; open-end, closed-end, self-plugging). To review any of those posts, please click on any of these links.

In this final installation, we’ll break down some other variations of blind rivets. There are many different styles of blind rivets for specific applications, including different types of structural blind rivets.

Structural blind rivets are required for applications requiring higher load and vibration tolerances. They have higher shear and pull-out strength than standard blind rivets. Many offer a wide grip range, while most have exceptional clamping force. While they’re not quite a replacement for a blind bolt, such as the Huck BOM, or heavy hex bolt, they are a great option when a standard blind rivet just won’t suffice.

Topics: Products (General), fasteners

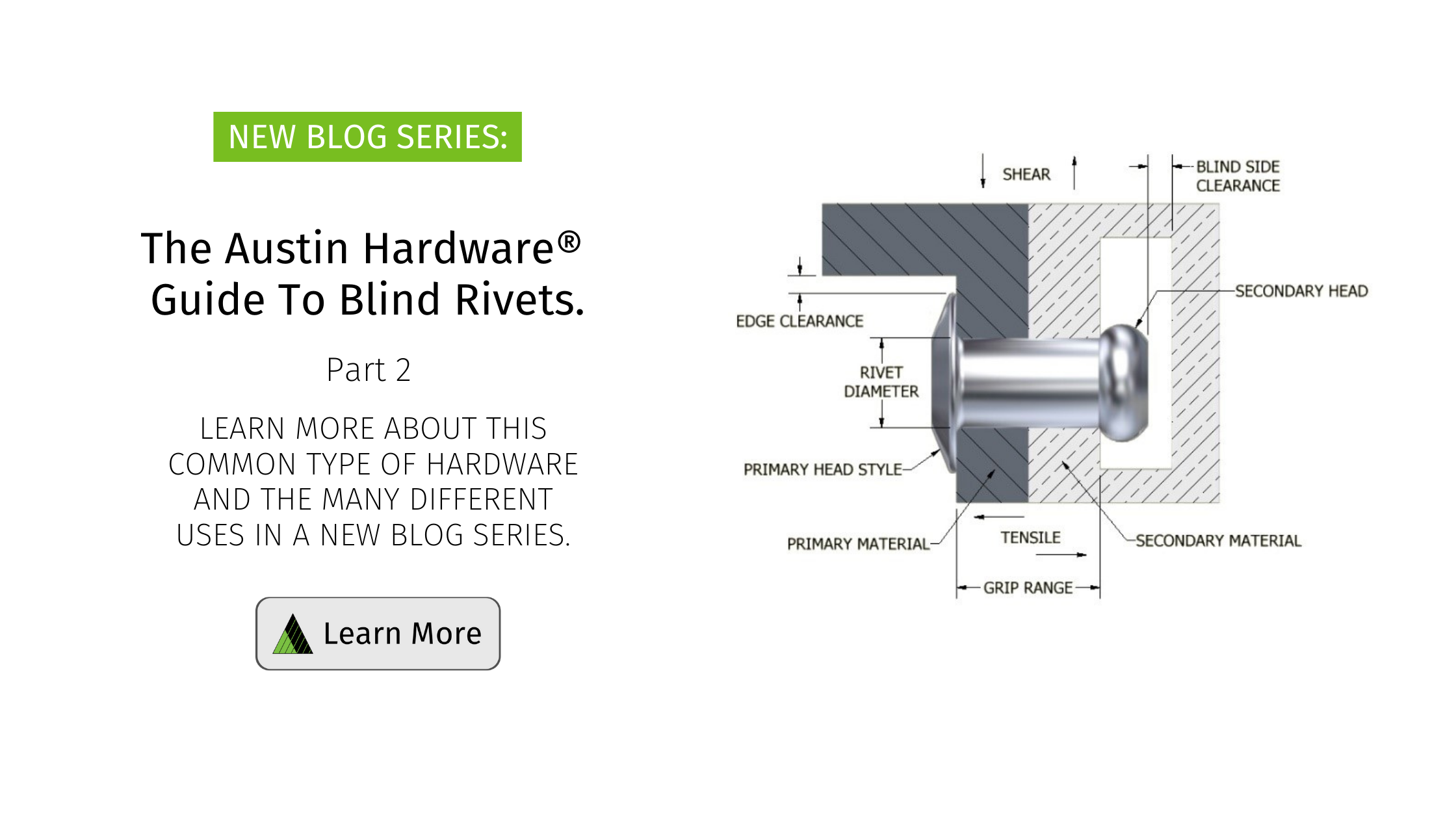

The Austin Hardware® Guide to Blind Rivets, Part Two

This is Part 2 of a 4-part series on Blind Rivets

In part one of our series on blind rivets, we briefly looked at the history of the blind (a.k.a. pop) rivet and discussed the two most important considerations to maximize joint integrity when using them: Grip Range and Hole Size. If you have not yet read that post, click HERE.

We'll now break down the third and fourth most important aspects to consider to maximize joint integrity using blind rivets: Material and Installation Tooling.

- Material - A good rule of thumb when selecting a blind rivet is to use the same material rivet as the substrate into which it's being installed. If you're riveting sheets of steel together, use a steel rivet. The same goes for aluminum and stainless steel. This is important because using dissimilar metals may result in galvanic corrosion, depending on the application's environment.

Installation Tooling - What role exactly does installation tooling play in how a blind rivet works? It's simple. An installation tool has one job … to pull the stem of the blind rivet up through the rivet body until the pull force of the tool overcomes the tensile strength of the rivet stem, resulting in the stem breaking off at its predetermined breakpoint.

There's nothing more to it than that. All strength parameters and application criteria of a properly installed blind rivet reside within the rivet itself. If the installation tool breaks off the blind rivet stem, it's done its job. So, this means that the primary consideration for blind rivet installation tooling is accessibility. Can the tool fit into the area around where the rivet needs to go? Fortunately, there are many different configurations and types of tooling available. So, in most cases, you'll find an installation tool that quite literally "fits" your needs.

Topics: fasteners